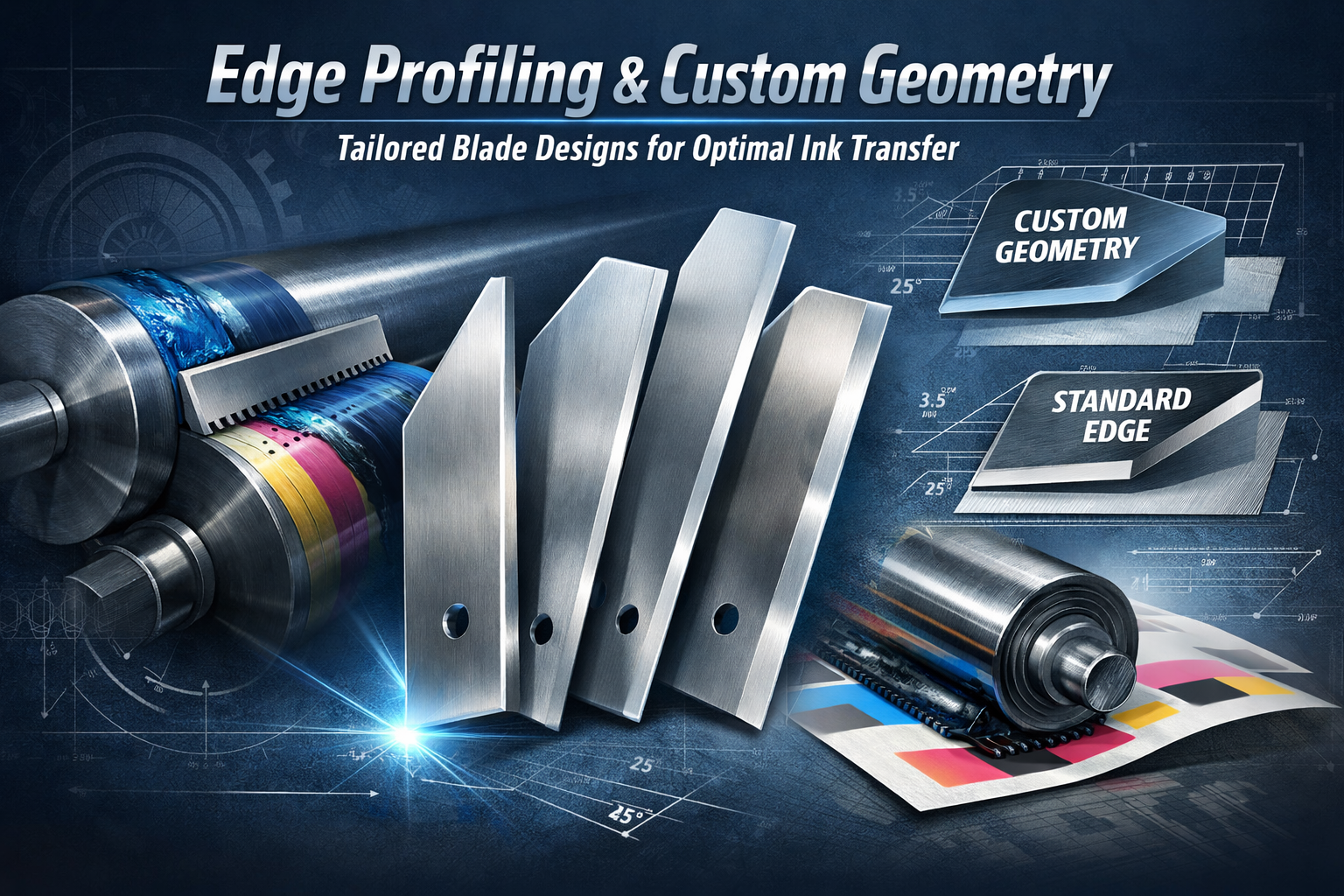

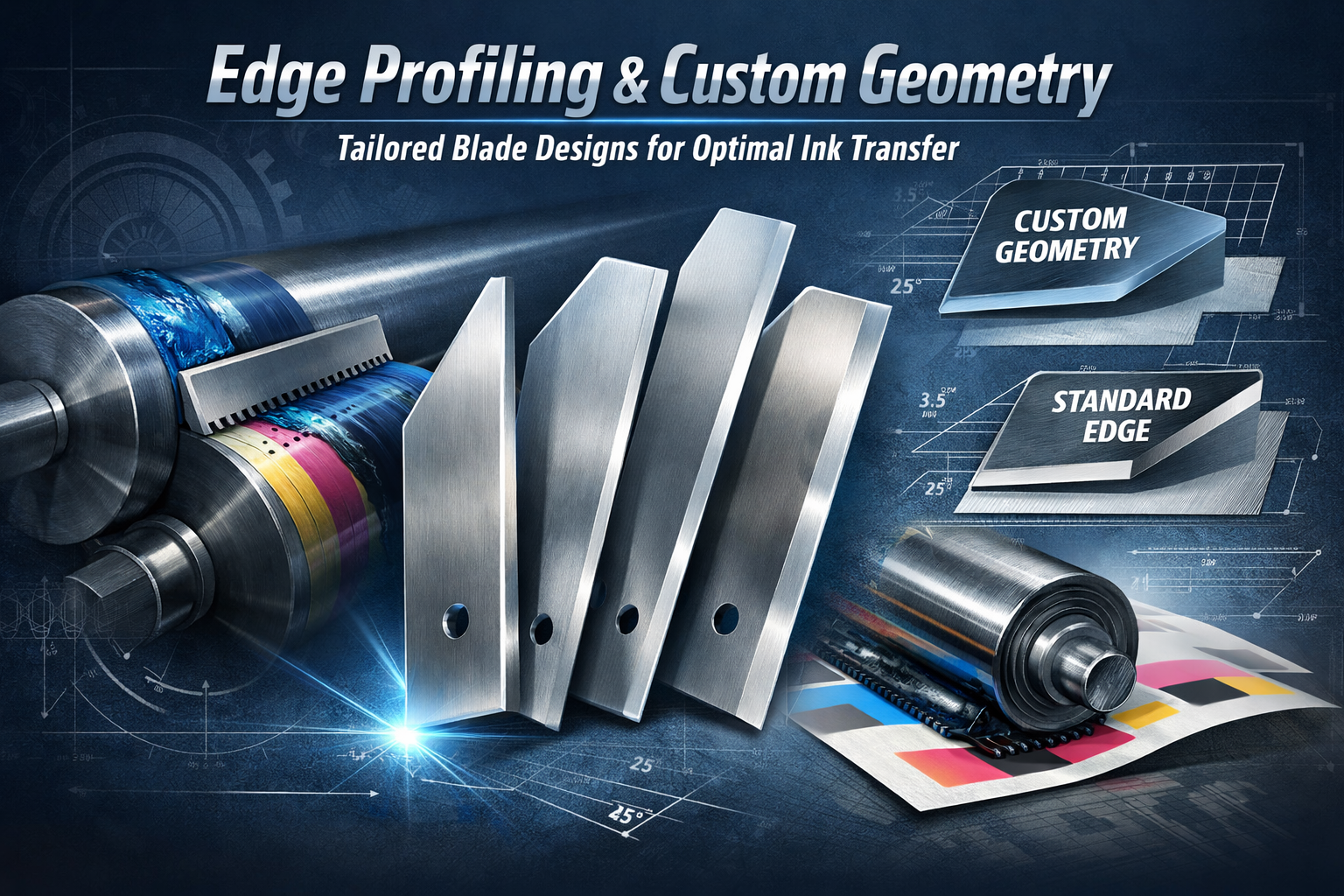

Edge Profiling & Custom Geometry

Precision edge design is a critical factor in achieving stable ink transfer and consistent print quality. Our Edge Profiling & Custom Geometry service is engineered to deliver doctor blades that are precisely matched to your press configuration, ink system, and production requirements. By optimizing blade edge geometry at a micro level, we help printing operations reduce variability, improve ink control, and extend component life.

Doctor blades are not generic consumables. The edge angle, profile shape, and surface finish directly influence how ink is metered from the anilox roll and transferred to the substrate. Even minor inconsistencies can lead to streaking, uneven ink laydown, excessive pressure, or premature anilox wear. Standard blade profiles often force operators to compensate through press adjustments, increasing downtime and operating costs.

Our custom edge profiling approach eliminates these compromises by designing blade geometries that work in harmony with real press conditions. Each blade is engineered to provide clean ink metering, stable contact, and predictable performance throughout the production run.

Simple Steps to Process

Our edge profiling and custom geometry process is designed to ensure that every doctor blade performs precisely according to your press conditions. We follow a structured, application-driven approach that eliminates guesswork and delivers consistent, press-ready results. From requirement analysis to final quality validation, each step is focused on improving ink control, print consistency, and operational efficiency.

- Application and press condition assessment

- Ink type, anilox volume, and substrate analysis

- Selection of optimal blade angle and edge profile

- Precision edge profiling and controlled finishing

- Final inspection and performance validation

Customer Benefits

Custom edge profiling delivers measurable performance advantages by aligning blade geometry with real production conditions. Instead of adapting the press to compensate for standard blades, this service ensures the blade works in harmony with the press. The result is stable ink metering, reduced component wear, and consistent print quality across short and long production runs. Printers benefit from improved operational control, fewer adjustments, and lower overall production costs.

- Consistent and accurate ink metering

- Reduced print defects and color variation

- Lower blade and anilox roll wear

- Faster setup and fewer press adjustments

- Improved uptime and production efficiency

By eliminating variability at the blade edge, custom geometry enhances repeatability and reliability on the press floor. This leads to reduced waste, fewer stoppages, and predictable performance—making edge profiling a strategic investment rather than a consumable expense.