Doctor Blades Explained: Choosing the Right Material for Precision Ink Control and Long Press Performance

Doctor Blades Explained: Choosing the Right Material for Precision Ink Control and Long Press Performance – In modern flexographic and rotogravure printing, doctor blades play a critical role in controlling ink transfer, maintaining print clarity, and protecting press components. The right blade does far more than meter ink — it stabilizes production, reduces downtime, and improves consistency across long runs. As printing speeds increase and ink systems become more specialized, blade material selection becomes a strategic decision rather than a routine replacement choice.

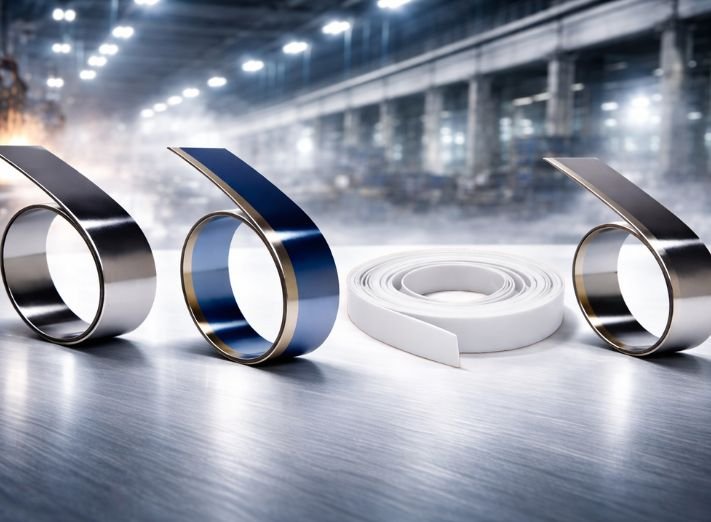

This guide explains how different doctor blade materials behave in real production environments and how to select the optimal blade for durability, substrate protection, and ink control. We’ll explore four engineered blade categories — High Carbon Steel, Long Life, Polymer, and Stainless Steel — and examine their performance advantages, technical characteristics, and ideal applications.

Why Doctor Blade Selection Matters

Doctor blades regulate the ink film thickness on anilox rolls or gravure cylinders. A poorly matched blade can cause streaking, uneven ink transfer, premature wear, or press vibration. In contrast, a properly engineered blade ensures:

- Stable ink metering

- Clean doctoring action

- Reduced cylinder wear

- Extended production cycles

- Consistent print quality

Material composition, lamella geometry, and surface finish all influence blade behavior under pressure and speed. Different printing environments — abrasive inks, sensitive substrates, high humidity, or high-speed operations — demand tailored blade solutions.

High Carbon Steel Doctor Blades: Precision and Durability

High Carbon Steel Doctor Blades are engineered for applications requiring tight dimensional accuracy and long-term edge stability. Manufactured from premium-grade steel using CNC lamella grinding, these blades deliver micron-level precision that supports uniform ink metering and reliable print output.

Their optimized surface finish reduces friction against cylinders, minimizing wear while maintaining strong edge retention. This makes them particularly effective in high-speed operations where consistent blade contact is essential.

Key advantages include:

- Micron-level lamella accuracy

- Excellent edge retention

- Reduced cylinder wear

- Uniform pressure distribution

- Stable long-run performance

Typical technical range:

- Width: 10–80 mm

- Thickness: 0.15–0.30 mm

- Lamella tolerance: ±0.005 mm

Recommended environments:

- Rotogravure presses

- Flexographic printing

- Enclosed chamber systems

- Solvent, water-based, and UV inks

These blades are ideal when precision and repeatability are non-negotiable.

Long Life Doctor Blades: Built for Extended Production

Long Life Doctor Blades are designed for abrasive ink systems and continuous high-volume production. Their advanced wear-resistant construction significantly reduces blade replacement frequency, improving uptime and lowering operational costs.

Precision lamella geometry maintains stable ink metering even under aggressive printing conditions. These blades are especially valuable for converters running long production cycles where stoppages directly affect profitability.

Performance benefits:

- Exceptional wear resistance

- Reduced blade change intervals

- Stable ink control during extended runs

- Lower maintenance interruptions

Typical specifications:

- Width: 20–60 mm

- Standard lamella geometry

Common applications:

- Abrasive ink systems

- High-speed printing

- Industrial flexo and gravure presses

When productivity and blade longevity are priorities, long-life blades deliver measurable operational advantages.

Polymer Doctor Blades: Gentle Control for Sensitive Surfaces

Polymer Doctor Blades provide low-friction doctoring that protects delicate substrates and specialty coatings. Engineered polymer formulations minimize drag, vibration, and streaking while maintaining consistent pressure distribution.

Unlike metal blades, polymer variants flex slightly under load, allowing smoother contact with sensitive surfaces. This makes them ideal for applications where substrate protection is critical.

Key performance characteristics:

- Gentle doctoring action

- Reduced surface wear

- Stable pressure distribution

- Low vibration operation

Typical specifications:

- Width: 30–35 mm

- Thickness: 0.70 mm

- Custom lamella options available

Common applications:

- Sensitive substrates

- Coatings and adhesives

- Specialty printing systems

- Low-friction doctoring requirements

Polymer blades are a preferred solution when precision must be balanced with surface protection.

Stainless Steel Doctor Blades: Corrosion-Resistant Reliability

Stainless Steel Doctor Blades are developed for environments where moisture, aggressive chemistries, or specialty inks would degrade conventional steel. Premium stainless alloys resist corrosion while maintaining lamella integrity and edge stability.

Precision grinding and automated quality inspection ensure consistent thickness and straightness, enabling predictable ink control and longer blade life.

Advantages include:

- Corrosion resistance

- Stable lamella contact

- Reduced blade change frequency

- Reliable performance in wet environments

Technical range:

- Width: 20–60 mm

- Thickness: 0.15–0.30 mm

- Lamella tolerance: ±0.005 mm

Applications:

- Water-based ink systems

- Solvent and specialty inks

- Flexographic presses

- Enclosed ink chambers

These blades are essential where environmental exposure demands material resilience.

Matching Blade Type to Production Goals

Selecting the right blade involves evaluating:

- Ink abrasiveness

- Press speed

- Substrate sensitivity

- Environmental exposure

- Maintenance goals

High carbon steel blades emphasize precision. Long life blades reduce downtime. Polymer blades protect surfaces. Stainless steel blades handle chemical exposure. Understanding how each behaves under pressure allows printers to optimize output while protecting equipment.

Operational Impact of Proper Blade Selection

When blade material aligns with application requirements, printers benefit from:

- Cleaner ink transfer

- Reduced streaking

- Longer production cycles

- Lower maintenance costs

- Improved press stability

Blade choice is not just a consumable decision — it is a performance strategy influencing quality, efficiency, and component lifespan.

Final Conclusion

Doctor blades are engineered tools that directly influence print consistency, press longevity, and operational efficiency. High carbon steel, long life, polymer, and stainless steel blades each serve distinct production needs. By aligning blade properties with application demands, printers achieve predictable ink control, reduced downtime, and reliable performance across every production cycle.

Understanding blade behavior transforms routine maintenance into a proactive optimization strategy — ensuring every press run delivers consistent results.

Frequently Asked Questions

1. How do I know which doctor blade material is best for my press?

Selection depends on ink type, press speed, substrate sensitivity, and production volume. Matching blade properties to operating conditions ensures optimal performance.

2. Can the wrong blade damage cylinders or anilox rolls?

Yes. Improper blade hardness or geometry can increase friction, leading to premature wear and inconsistent ink transfer.

3. Are polymer blades less durable than metal blades?

Polymer blades prioritize surface protection and low friction. They are durable within their intended applications, especially for delicate materials.

4. How do long life blades reduce operating costs?

Their wear-resistant construction reduces replacement frequency, minimizing downtime and maintenance labor.

5. Why choose stainless steel blades for water-based inks?

Stainless alloys resist corrosion, maintaining blade integrity in moisture-rich environments.

6. Does lamella precision really affect print quality?

Absolutely. Micron-level accuracy ensures uniform ink metering, directly influencing print consistency and clarity.

For more details and High Quality Doctor Blades Contact Supertech today.

Get In Touch With Us:

Office Address K.B. Lal Industrial Estate, Gala No. 7, Linking Road EXTN, Santacruz (W), Mumbai – 400054, India

Phone Number +91 9930042200 A

Email: sales@supertechblades.com

Reference: Doctor blade